3329 changed files with 2770906 additions and 0 deletions

-

94AUTHORS

-

80CMakeLists.txt

-

14Dockerfile

-

31JLinkSettings.ini

-

674LICENSE

-

83README.md

-

32Vagrantfile

-

32build.sh

-

60build_docs.sh

-

172cmake/GetGitRevisionDescription.cmake

-

41cmake/GetGitRevisionDescription.cmake.in

-

119cmake/arm-none-eabi-checks.cmake

-

48cmake/arm-none-eabi.cmake

-

15cmake/ci.cmake

-

23cmake/cortex-m4f.cmake

-

22cmake/cortex-m7.cmake

-

29cmake/docker.sh

-

34cmake/gcc.cmake

-

121cmake/main.cmake

-

84cmake/openocd.cmake

-

20cmake/openocd_cfg.cmake

-

41cmake/settings.cmake

-

30cmake/stm32-bootloader.cmake

-

4cmake/stm32-stdperiph.cmake

-

437cmake/stm32.cmake

-

16cmake/stm32f3-usb.cmake

-

95cmake/stm32f3.cmake

-

59cmake/stm32f4-usb.cmake

-

155cmake/stm32f4.cmake

-

48cmake/stm32f7-usb.cmake

-

140cmake/stm32f7.cmake

-

41cmake/stm32h7-usb.cmake

-

220cmake/stm32h7.cmake

-

16cmake/svd.cmake

-

40381dev/svd/STM32F303.svd

-

61681dev/svd/STM32F405.svd

-

27110dev/svd/STM32F411.svd

-

63121dev/svd/STM32F427.svd

-

57155dev/svd/STM32F446.svd

-

61861dev/svd/STM32F7x2.svd

-

71136dev/svd/STM32F7x5.svd

-

70681dev/svd/STM32F7x6.svd

-

28dev/vscode/launch.json

-

51dev/vscode/tasks.json

-

74docs/1wire.md

-

161docs/API/MSP_extensions.md

-

59docs/Autotune - fixedwing.md

-

324docs/Battery.md

-

262docs/Blackbox.md

-

85docs/Board - Airbot F4 and Flip32 F4.md

-

71docs/Board - AlienFlight.md

-

86docs/Board - AnyFC F7.md

-

60docs/Board - BeeRotor F4.md

-

12docs/Board - BetFPVF722.md

-

106docs/Board - DALRCF405.md

-

111docs/Board - DALRCF722DUAL.md

-

33docs/Board - FLYWOOF411.md

-

16docs/Board - FOXEERF405.md

-

103docs/Board - FOXEERF722DUAL.md

-

13docs/Board - FrSky Pilot.md

-

19docs/Board - IFLIGHTF7_TWING.md

-

23docs/Board - KroozX.md

-

30docs/Board - Matek F411 Wing.md

-

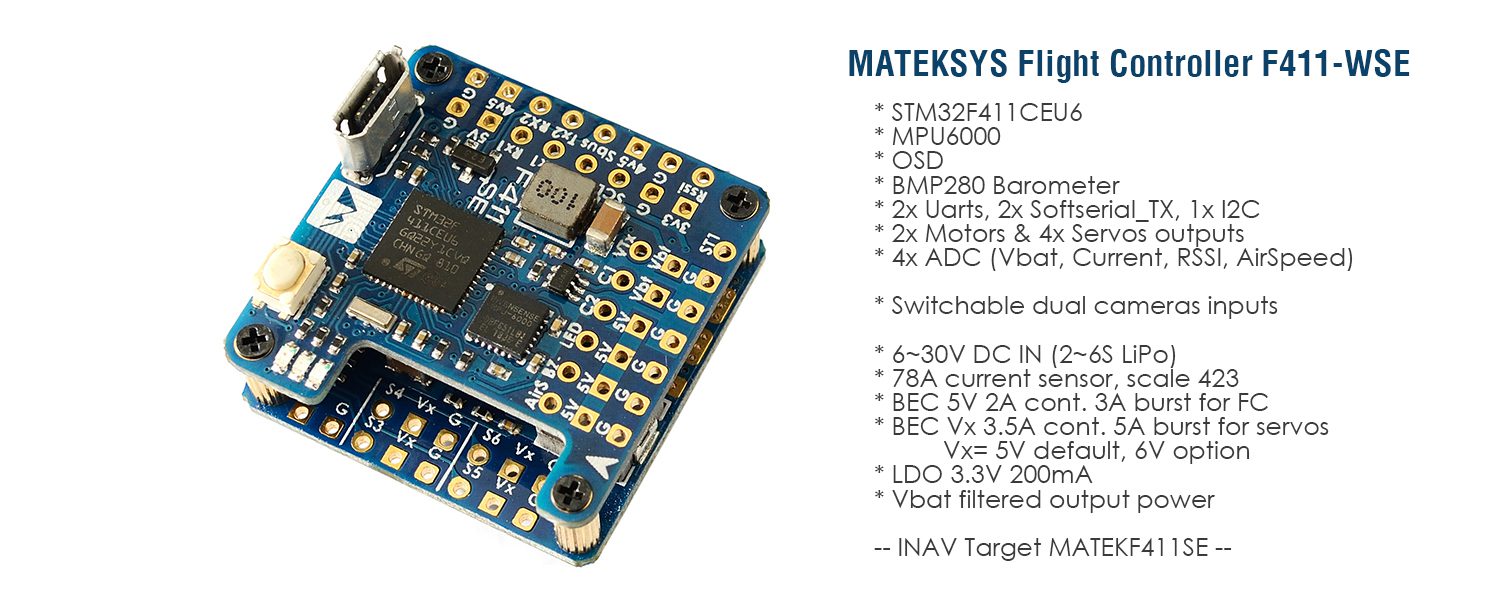

26docs/Board - Matek F411-WSE.md

-

25docs/Board - Matek F722-STD.md

-

25docs/Board - MatekF405 Wing.md

-

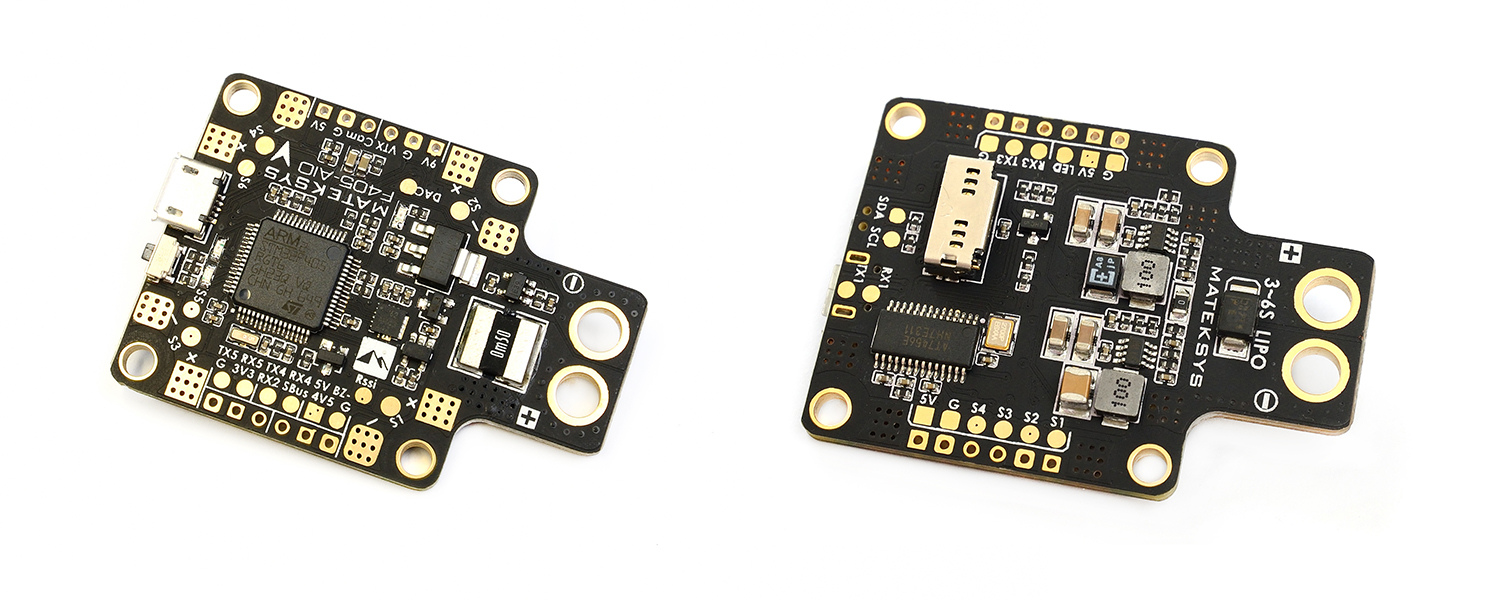

124docs/Board - MatekF405.md

-

92docs/Board - MatekF722-SE.md

-

14docs/Board - MatekF722.md

-

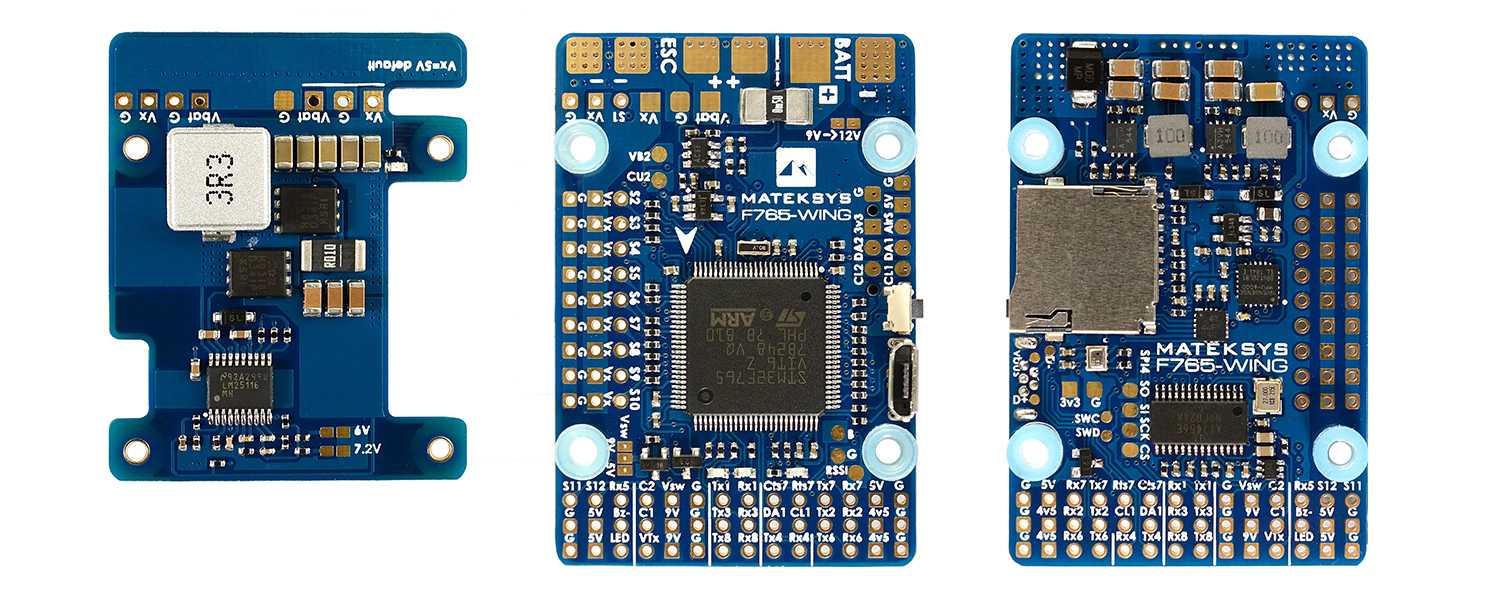

28docs/Board - MatekF765-Wing.md

-

46docs/Board - NOX.md

-

202docs/Board - Omnibus F4.md

-

43docs/Board - Omnibus F7.md

-

94docs/Board - PixRacer R14.md

-

132docs/Board - Revolution.md

-

12docs/Board - WingFC.md

-

38docs/Board - YuPiF4.md

-

49docs/Boards.md

-

99docs/Buzzer.md

-

15docs/Channel forwarding.md

-

150docs/Cli.md

-

35docs/Configuration.md

-

97docs/Controls.md

-

75docs/Display.md

-

26docs/ESC and servo outputs.md

-

146docs/Failsafe.md

-

107docs/Getting Started.md

-

25docs/INAV PID Controller.md

-

BINdocs/INAV_Autolaunch.pdf

-

BINdocs/INAV_Fixed_Wing_Setup_Guide.pdf

-

BINdocs/INAV_Modes.pdf

-

BINdocs/INAV_Wing_Tuning_Masterclass.pdf

-

266docs/Inflight Adjustments.md

-

30docs/Installation.md

-

35docs/Introduction.md

-

599docs/LedStrip.md

-

33docs/Lights.md

-

106docs/Mixer.md

-

112docs/Navigation.md

-

79docs/PID tuning.md

@ -0,0 +1,94 @@ |

|||

This is at least a partial credits-file of people that have contributed to the INAV project. |

|||

If you believe you should be on this list - feel free to open a PR updating it. For faster |

|||

inclusion into this list please provide information about which part of code belongs to you. |

|||

|

|||

Albert Kravcov |

|||

Alberto García Hierro |

|||

Alex Gorbatchev |

|||

Alex Zaitsev |

|||

Alexander Fedorov |

|||

Alexander van Saase |

|||

Alexey Stankevich |

|||

Andre Bernet |

|||

Andreas Tacke |

|||

Andrew Payne |

|||

Austin St. Aubin |

|||

Bas Huisman |

|||

Ben Hitchcock |

|||

Boris B |

|||

Brnadon Miller |

|||

ChiggerPepi |

|||

Chris Campbell |

|||

Chris Mavrakis |

|||

Chris Nisbet |

|||

Chris Penny |

|||

Damjan Adamic |

|||

Dave Pitman |

|||

David Bieber |

|||

Davide Bertola |

|||

Denis Kisselev |

|||

Dominic Clifton |

|||

Frank Zhao |

|||

Fredrik Steen |

|||

Gareth Wilkins |

|||

Gaël James |

|||

Gregor Ottmann |

|||

Google LLC |

|||

Hyon Lim |

|||

Hubert Jozwiak |

|||

James Harrison |

|||

Jan Staal |

|||

Jeremy Waters |

|||

Joe Hermaszewski |

|||

Joe Poser |

|||

Joel Fuster |

|||

Johannes Kasberger |

|||

Jonas Harnesk |

|||

Jonathan Hudson |

|||

Joshua Bardwell |

|||

Juan González |

|||

Kemal Hadimli |

|||

Kieran Moore |

|||

Konstantin Sharlaimov |

|||

Krzysztof Rosinski |

|||

Kyle Manna |

|||

Larry Davis |

|||

Marc Egli |

|||

Mark Williams |

|||

Martin Budden |

|||

Matthew Evans |

|||

Mauro Mombelli |

|||

Max Winterstein |

|||

Michael Corcoran |

|||

Michael Hope |

|||

Michael Jakob |

|||

Michel Pastor |

|||

Miha Valencic |

|||

Mikael Blomqvist |

|||

Moritz Ulrich |

|||

Moshen Chan |

|||

Nathan Tsoi |

|||

Nicholas Sherlock |

|||

Paul Fertser |

|||

Paul Rogalinski |

|||

Pawel Spychalski |

|||

Petr Ledvina |

|||

Phillip Jones |

|||

Pierre Hugo |

|||

Richard Birkby |

|||

Richard Lehey |

|||

Richard Marko |

|||

Rimas Avizienis |

|||

Sam Cook |

|||

Sami Korhonen |

|||

Samuel Brucksch |

|||

Scott Shawcroft |

|||

Sean Vig |

|||

Stefan Grufman |

|||

Stefan Haubold |

|||

Steve Amor |

|||

Thomas Buck |

|||

Tim Eckel |

|||

Trey Marc |

|||

Tuomas Kuosmanen |

|||

Zap Andersson |

|||

@ -0,0 +1,80 @@ |

|||

cmake_minimum_required(VERSION 3.13...3.18) |

|||

|

|||

list(APPEND CMAKE_MODULE_PATH "${CMAKE_CURRENT_SOURCE_DIR}/cmake") |

|||

|

|||

set(MAIN_DIR "${CMAKE_CURRENT_SOURCE_DIR}") |

|||

set(MAIN_LIB_DIR "${CMAKE_CURRENT_SOURCE_DIR}/lib") |

|||

set(MAIN_UTILS_DIR "${CMAKE_CURRENT_SOURCE_DIR}/src/utils") |

|||

set(MAIN_SRC_DIR "${CMAKE_CURRENT_SOURCE_DIR}/src/main") |

|||

set(SVD_DIR "${CMAKE_CURRENT_SOURCE_DIR}/dev/svd") |

|||

set(DOWNLOADS_DIR "${MAIN_DIR}/downloads") |

|||

set(TOOLS_DIR "${MAIN_DIR}/tools") |

|||

|

|||

set(TOOLCHAIN_OPTIONS none arm-none-eabi) |

|||

set(TOOLCHAIN "arm-none-eabi" CACHE STRING "Toolchain to use. Available: ${TOOLCHAIN_OPTIONS}") |

|||

set_property(CACHE TOOLCHAIN PROPERTY STRINGS ${TOOLCHAIN_OPTIONS}) |

|||

if("" STREQUAL TOOLCHAIN) |

|||

set(TOOLCHAIN none) |

|||

endif() |

|||

if (NOT ${TOOLCHAIN} IN_LIST TOOLCHAIN_OPTIONS) |

|||

message(FATAL_ERROR "Invalid toolchain ${TOOLCHAIN}. Valid options are: ${TOOLCHAIN_OPTIONS}") |

|||

endif() |

|||

|

|||

option(COMPILER_VERSION_CHECK "Ensure the compiler matches the expected version" ON) |

|||

|

|||

include(GetGitRevisionDescription) |

|||

get_git_head_revision(GIT_REFSPEC GIT_SHA1) |

|||

string(SUBSTRING ${GIT_SHA1} 0 8 GIT_REV) |

|||

|

|||

# Load settings related functions, so the tests can use them |

|||

include(main) |

|||

include(settings) |

|||

|

|||

if(TOOLCHAIN STREQUAL none) |

|||

add_subdirectory(src/test) |

|||

else() |

|||

set(CMAKE_TOOLCHAIN_FILE "${CMAKE_CURRENT_SOURCE_DIR}/cmake/${TOOLCHAIN}.cmake") |

|||

include("${CMAKE_CURRENT_SOURCE_DIR}/cmake/${TOOLCHAIN}-checks.cmake") |

|||

endif() |

|||

|

|||

project(INAV VERSION 3.1.0) |

|||

|

|||

enable_language(ASM) |

|||

|

|||

set(CMAKE_C_STANDARD 99) |

|||

set(CMAKE_C_EXTENSIONS ON) |

|||

set(CMAKE_C_STANDARD_REQUIRED ON) |

|||

set(CMAKE_CXX_STANDARD 11) |

|||

set(CMAKE_CXX_EXTENSIONS ON) |

|||

set(CMAKE_CXX_STANDARD_REQUIRED ON) |

|||

|

|||

find_program(RUBY_EXECUTABLE ruby) |

|||

if (NOT RUBY_EXECUTABLE) |

|||

message(FATAL_ERROR "Could not find ruby") |

|||

endif() |

|||

|

|||

if(CMAKE_BUILD_TYPE STREQUAL "Release" OR CMAKE_BUILD_TYPE STREQUAL "RelWithDebInfo") |

|||

set(IS_RELEASE_BUILD ON) |

|||

endif() |

|||

|

|||

set(FIRMWARE_VERSION ${PROJECT_VERSION}) |

|||

|

|||

option(WARNINGS_AS_ERRORS "Make all warnings into errors") |

|||

message("-- toolchain: ${TOOLCHAIN}, WARNINGS_AS_ERRORS: ${WARNINGS_AS_ERRORS}") |

|||

|

|||

set(COMMON_COMPILE_DEFINITIONS |

|||

FC_VERSION_MAJOR=${CMAKE_PROJECT_VERSION_MAJOR} |

|||

FC_VERSION_MINOR=${CMAKE_PROJECT_VERSION_MINOR} |

|||

FC_VERSION_PATCH_LEVEL=${CMAKE_PROJECT_VERSION_PATCH} |

|||

) |

|||

|

|||

include(openocd) |

|||

include(svd) |

|||

include(stm32) |

|||

|

|||

add_subdirectory(src) |

|||

|

|||

collect_targets() |

|||

|

|||

message("-- Build type: ${CMAKE_BUILD_TYPE}") |

|||

include(ci) |

|||

@ -0,0 +1,14 @@ |

|||

FROM ubuntu:focal |

|||

|

|||

ENV DEBIAN_FRONTEND noninteractive |

|||

|

|||

RUN apt-get update && apt-get install -y git cmake make ruby gcc |

|||

|

|||

RUN useradd inav |

|||

|

|||

USER inav |

|||

|

|||

VOLUME /src |

|||

|

|||

WORKDIR /src/build |

|||

ENTRYPOINT ["/src/cmake/docker.sh"] |

|||

@ -0,0 +1,31 @@ |

|||

[BREAKPOINTS] |

|||

ShowInfoWin = 1 |

|||

EnableFlashBP = 2 |

|||

BPDuringExecution = 0 |

|||

[CFI] |

|||

CFISize = 0x00 |

|||

CFIAddr = 0x00 |

|||

[CPU] |

|||

OverrideMemMap = 0 |

|||

AllowSimulation = 1 |

|||

ScriptFile="" |

|||

[FLASH] |

|||

MinNumBytesFlashDL = 0 |

|||

SkipProgOnCRCMatch = 1 |

|||

VerifyDownload = 1 |

|||

AllowCaching = 1 |

|||

EnableFlashDL = 2 |

|||

Override = 0 |

|||

Device="AD7160" |

|||

[GENERAL] |

|||

WorkRAMSize = 0x00 |

|||

WorkRAMAddr = 0x00 |

|||

[SWO] |

|||

SWOLogFile="" |

|||

[MEM] |

|||

RdOverrideOrMask = 0x00 |

|||

RdOverrideAndMask = 0xFFFFFFFF |

|||

RdOverrideAddr = 0xFFFFFFFF |

|||

WrOverrideOrMask = 0x00 |

|||

WrOverrideAndMask = 0xFFFFFFFF |

|||

WrOverrideAddr = 0xFFFFFFFF |

|||

@ -0,0 +1,674 @@ |

|||

GNU GENERAL PUBLIC LICENSE |

|||

Version 3, 29 June 2007 |

|||

|

|||

Copyright (C) 2007 Free Software Foundation, Inc. <http://fsf.org/> |

|||

Everyone is permitted to copy and distribute verbatim copies |

|||

of this license document, but changing it is not allowed. |

|||

|

|||

Preamble |

|||

|

|||

The GNU General Public License is a free, copyleft license for |

|||

software and other kinds of works. |

|||

|

|||

The licenses for most software and other practical works are designed |

|||

to take away your freedom to share and change the works. By contrast, |

|||

the GNU General Public License is intended to guarantee your freedom to |

|||

share and change all versions of a program--to make sure it remains free |

|||

software for all its users. We, the Free Software Foundation, use the |

|||

GNU General Public License for most of our software; it applies also to |

|||

any other work released this way by its authors. You can apply it to |

|||

your programs, too. |

|||

|

|||

When we speak of free software, we are referring to freedom, not |

|||

price. Our General Public Licenses are designed to make sure that you |

|||

have the freedom to distribute copies of free software (and charge for |

|||

them if you wish), that you receive source code or can get it if you |

|||

want it, that you can change the software or use pieces of it in new |

|||

free programs, and that you know you can do these things. |

|||

|

|||

To protect your rights, we need to prevent others from denying you |

|||

these rights or asking you to surrender the rights. Therefore, you have |

|||

certain responsibilities if you distribute copies of the software, or if |

|||

you modify it: responsibilities to respect the freedom of others. |

|||

|

|||

For example, if you distribute copies of such a program, whether |

|||

gratis or for a fee, you must pass on to the recipients the same |

|||

freedoms that you received. You must make sure that they, too, receive |

|||

or can get the source code. And you must show them these terms so they |

|||

know their rights. |

|||

|

|||

Developers that use the GNU GPL protect your rights with two steps: |

|||

(1) assert copyright on the software, and (2) offer you this License |

|||

giving you legal permission to copy, distribute and/or modify it. |

|||

|

|||

For the developers' and authors' protection, the GPL clearly explains |

|||

that there is no warranty for this free software. For both users' and |

|||

authors' sake, the GPL requires that modified versions be marked as |

|||

changed, so that their problems will not be attributed erroneously to |

|||

authors of previous versions. |

|||

|

|||

Some devices are designed to deny users access to install or run |

|||

modified versions of the software inside them, although the manufacturer |

|||

can do so. This is fundamentally incompatible with the aim of |

|||

protecting users' freedom to change the software. The systematic |

|||

pattern of such abuse occurs in the area of products for individuals to |

|||

use, which is precisely where it is most unacceptable. Therefore, we |

|||

have designed this version of the GPL to prohibit the practice for those |

|||

products. If such problems arise substantially in other domains, we |

|||

stand ready to extend this provision to those domains in future versions |

|||

of the GPL, as needed to protect the freedom of users. |

|||

|

|||

Finally, every program is threatened constantly by software patents. |

|||

States should not allow patents to restrict development and use of |

|||

software on general-purpose computers, but in those that do, we wish to |

|||

avoid the special danger that patents applied to a free program could |

|||

make it effectively proprietary. To prevent this, the GPL assures that |

|||

patents cannot be used to render the program non-free. |

|||

|

|||

The precise terms and conditions for copying, distribution and |

|||

modification follow. |

|||

|

|||

TERMS AND CONDITIONS |

|||

|

|||

0. Definitions. |

|||

|

|||

"This License" refers to version 3 of the GNU General Public License. |

|||

|

|||

"Copyright" also means copyright-like laws that apply to other kinds of |

|||

works, such as semiconductor masks. |

|||

|

|||

"The Program" refers to any copyrightable work licensed under this |

|||

License. Each licensee is addressed as "you". "Licensees" and |

|||

"recipients" may be individuals or organizations. |

|||

|

|||

To "modify" a work means to copy from or adapt all or part of the work |

|||

in a fashion requiring copyright permission, other than the making of an |

|||

exact copy. The resulting work is called a "modified version" of the |

|||

earlier work or a work "based on" the earlier work. |

|||

|

|||

A "covered work" means either the unmodified Program or a work based |

|||

on the Program. |

|||

|

|||

To "propagate" a work means to do anything with it that, without |

|||

permission, would make you directly or secondarily liable for |

|||

infringement under applicable copyright law, except executing it on a |

|||

computer or modifying a private copy. Propagation includes copying, |

|||

distribution (with or without modification), making available to the |

|||

public, and in some countries other activities as well. |

|||

|

|||

To "convey" a work means any kind of propagation that enables other |

|||

parties to make or receive copies. Mere interaction with a user through |

|||

a computer network, with no transfer of a copy, is not conveying. |

|||

|

|||

An interactive user interface displays "Appropriate Legal Notices" |

|||

to the extent that it includes a convenient and prominently visible |

|||

feature that (1) displays an appropriate copyright notice, and (2) |

|||

tells the user that there is no warranty for the work (except to the |

|||

extent that warranties are provided), that licensees may convey the |

|||

work under this License, and how to view a copy of this License. If |

|||

the interface presents a list of user commands or options, such as a |

|||

menu, a prominent item in the list meets this criterion. |

|||

|

|||

1. Source Code. |

|||

|

|||

The "source code" for a work means the preferred form of the work |

|||

for making modifications to it. "Object code" means any non-source |

|||

form of a work. |

|||

|

|||

A "Standard Interface" means an interface that either is an official |

|||

standard defined by a recognized standards body, or, in the case of |

|||

interfaces specified for a particular programming language, one that |

|||

is widely used among developers working in that language. |

|||

|

|||

The "System Libraries" of an executable work include anything, other |

|||

than the work as a whole, that (a) is included in the normal form of |

|||

packaging a Major Component, but which is not part of that Major |

|||

Component, and (b) serves only to enable use of the work with that |

|||

Major Component, or to implement a Standard Interface for which an |

|||

implementation is available to the public in source code form. A |

|||

"Major Component", in this context, means a major essential component |

|||

(kernel, window system, and so on) of the specific operating system |

|||

(if any) on which the executable work runs, or a compiler used to |

|||

produce the work, or an object code interpreter used to run it. |

|||

|

|||

The "Corresponding Source" for a work in object code form means all |

|||

the source code needed to generate, install, and (for an executable |

|||

work) run the object code and to modify the work, including scripts to |

|||

control those activities. However, it does not include the work's |

|||

System Libraries, or general-purpose tools or generally available free |

|||

programs which are used unmodified in performing those activities but |

|||

which are not part of the work. For example, Corresponding Source |

|||

includes interface definition files associated with source files for |

|||

the work, and the source code for shared libraries and dynamically |

|||

linked subprograms that the work is specifically designed to require, |

|||

such as by intimate data communication or control flow between those |

|||

subprograms and other parts of the work. |

|||

|

|||

The Corresponding Source need not include anything that users |

|||

can regenerate automatically from other parts of the Corresponding |

|||

Source. |

|||

|

|||

The Corresponding Source for a work in source code form is that |

|||

same work. |

|||

|

|||

2. Basic Permissions. |

|||

|

|||

All rights granted under this License are granted for the term of |

|||

copyright on the Program, and are irrevocable provided the stated |

|||

conditions are met. This License explicitly affirms your unlimited |

|||

permission to run the unmodified Program. The output from running a |

|||

covered work is covered by this License only if the output, given its |

|||

content, constitutes a covered work. This License acknowledges your |

|||

rights of fair use or other equivalent, as provided by copyright law. |

|||

|

|||

You may make, run and propagate covered works that you do not |

|||

convey, without conditions so long as your license otherwise remains |

|||

in force. You may convey covered works to others for the sole purpose |

|||

of having them make modifications exclusively for you, or provide you |

|||

with facilities for running those works, provided that you comply with |

|||

the terms of this License in conveying all material for which you do |

|||

not control copyright. Those thus making or running the covered works |

|||

for you must do so exclusively on your behalf, under your direction |

|||

and control, on terms that prohibit them from making any copies of |

|||

your copyrighted material outside their relationship with you. |

|||

|

|||

Conveying under any other circumstances is permitted solely under |

|||

the conditions stated below. Sublicensing is not allowed; section 10 |

|||

makes it unnecessary. |

|||

|

|||

3. Protecting Users' Legal Rights From Anti-Circumvention Law. |

|||

|

|||

No covered work shall be deemed part of an effective technological |

|||

measure under any applicable law fulfilling obligations under article |

|||

11 of the WIPO copyright treaty adopted on 20 December 1996, or |

|||

similar laws prohibiting or restricting circumvention of such |

|||

measures. |

|||

|

|||

When you convey a covered work, you waive any legal power to forbid |

|||

circumvention of technological measures to the extent such circumvention |

|||

is effected by exercising rights under this License with respect to |

|||

the covered work, and you disclaim any intention to limit operation or |

|||

modification of the work as a means of enforcing, against the work's |

|||

users, your or third parties' legal rights to forbid circumvention of |

|||

technological measures. |

|||

|

|||

4. Conveying Verbatim Copies. |

|||

|

|||

You may convey verbatim copies of the Program's source code as you |

|||

receive it, in any medium, provided that you conspicuously and |

|||

appropriately publish on each copy an appropriate copyright notice; |

|||

keep intact all notices stating that this License and any |

|||

non-permissive terms added in accord with section 7 apply to the code; |

|||

keep intact all notices of the absence of any warranty; and give all |

|||

recipients a copy of this License along with the Program. |

|||

|

|||

You may charge any price or no price for each copy that you convey, |

|||

and you may offer support or warranty protection for a fee. |

|||

|

|||

5. Conveying Modified Source Versions. |

|||

|

|||

You may convey a work based on the Program, or the modifications to |

|||

produce it from the Program, in the form of source code under the |

|||

terms of section 4, provided that you also meet all of these conditions: |

|||

|

|||

a) The work must carry prominent notices stating that you modified |

|||

it, and giving a relevant date. |

|||

|

|||

b) The work must carry prominent notices stating that it is |

|||

released under this License and any conditions added under section |

|||

7. This requirement modifies the requirement in section 4 to |

|||

"keep intact all notices". |

|||

|

|||

c) You must license the entire work, as a whole, under this |

|||

License to anyone who comes into possession of a copy. This |

|||

License will therefore apply, along with any applicable section 7 |

|||

additional terms, to the whole of the work, and all its parts, |

|||

regardless of how they are packaged. This License gives no |

|||

permission to license the work in any other way, but it does not |

|||

invalidate such permission if you have separately received it. |

|||

|

|||

d) If the work has interactive user interfaces, each must display |

|||

Appropriate Legal Notices; however, if the Program has interactive |

|||

interfaces that do not display Appropriate Legal Notices, your |

|||

work need not make them do so. |

|||

|

|||

A compilation of a covered work with other separate and independent |

|||

works, which are not by their nature extensions of the covered work, |

|||

and which are not combined with it such as to form a larger program, |

|||

in or on a volume of a storage or distribution medium, is called an |

|||

"aggregate" if the compilation and its resulting copyright are not |

|||

used to limit the access or legal rights of the compilation's users |

|||

beyond what the individual works permit. Inclusion of a covered work |

|||

in an aggregate does not cause this License to apply to the other |

|||

parts of the aggregate. |

|||

|

|||

6. Conveying Non-Source Forms. |

|||

|

|||

You may convey a covered work in object code form under the terms |

|||

of sections 4 and 5, provided that you also convey the |

|||

machine-readable Corresponding Source under the terms of this License, |

|||

in one of these ways: |

|||

|

|||

a) Convey the object code in, or embodied in, a physical product |

|||

(including a physical distribution medium), accompanied by the |

|||

Corresponding Source fixed on a durable physical medium |

|||

customarily used for software interchange. |

|||

|

|||

b) Convey the object code in, or embodied in, a physical product |

|||

(including a physical distribution medium), accompanied by a |

|||

written offer, valid for at least three years and valid for as |

|||

long as you offer spare parts or customer support for that product |

|||

model, to give anyone who possesses the object code either (1) a |

|||

copy of the Corresponding Source for all the software in the |

|||

product that is covered by this License, on a durable physical |

|||

medium customarily used for software interchange, for a price no |

|||

more than your reasonable cost of physically performing this |

|||

conveying of source, or (2) access to copy the |

|||

Corresponding Source from a network server at no charge. |

|||

|

|||

c) Convey individual copies of the object code with a copy of the |

|||

written offer to provide the Corresponding Source. This |

|||

alternative is allowed only occasionally and noncommercially, and |

|||

only if you received the object code with such an offer, in accord |

|||

with subsection 6b. |

|||

|

|||

d) Convey the object code by offering access from a designated |

|||

place (gratis or for a charge), and offer equivalent access to the |

|||

Corresponding Source in the same way through the same place at no |

|||

further charge. You need not require recipients to copy the |

|||

Corresponding Source along with the object code. If the place to |

|||

copy the object code is a network server, the Corresponding Source |

|||

may be on a different server (operated by you or a third party) |

|||

that supports equivalent copying facilities, provided you maintain |

|||

clear directions next to the object code saying where to find the |

|||

Corresponding Source. Regardless of what server hosts the |

|||

Corresponding Source, you remain obligated to ensure that it is |

|||

available for as long as needed to satisfy these requirements. |

|||

|

|||

e) Convey the object code using peer-to-peer transmission, provided |

|||

you inform other peers where the object code and Corresponding |

|||

Source of the work are being offered to the general public at no |

|||

charge under subsection 6d. |

|||

|

|||

A separable portion of the object code, whose source code is excluded |

|||

from the Corresponding Source as a System Library, need not be |

|||

included in conveying the object code work. |

|||

|

|||

A "User Product" is either (1) a "consumer product", which means any |

|||

tangible personal property which is normally used for personal, family, |

|||

or household purposes, or (2) anything designed or sold for incorporation |

|||

into a dwelling. In determining whether a product is a consumer product, |

|||

doubtful cases shall be resolved in favor of coverage. For a particular |

|||

product received by a particular user, "normally used" refers to a |

|||

typical or common use of that class of product, regardless of the status |

|||

of the particular user or of the way in which the particular user |

|||

actually uses, or expects or is expected to use, the product. A product |

|||

is a consumer product regardless of whether the product has substantial |

|||

commercial, industrial or non-consumer uses, unless such uses represent |

|||

the only significant mode of use of the product. |

|||

|

|||

"Installation Information" for a User Product means any methods, |

|||

procedures, authorization keys, or other information required to install |

|||

and execute modified versions of a covered work in that User Product from |

|||

a modified version of its Corresponding Source. The information must |

|||

suffice to ensure that the continued functioning of the modified object |

|||

code is in no case prevented or interfered with solely because |

|||

modification has been made. |

|||

|

|||

If you convey an object code work under this section in, or with, or |

|||

specifically for use in, a User Product, and the conveying occurs as |

|||

part of a transaction in which the right of possession and use of the |

|||

User Product is transferred to the recipient in perpetuity or for a |

|||

fixed term (regardless of how the transaction is characterized), the |

|||

Corresponding Source conveyed under this section must be accompanied |

|||

by the Installation Information. But this requirement does not apply |

|||

if neither you nor any third party retains the ability to install |

|||

modified object code on the User Product (for example, the work has |

|||

been installed in ROM). |

|||

|

|||

The requirement to provide Installation Information does not include a |

|||

requirement to continue to provide support service, warranty, or updates |

|||

for a work that has been modified or installed by the recipient, or for |

|||

the User Product in which it has been modified or installed. Access to a |

|||

network may be denied when the modification itself materially and |

|||

adversely affects the operation of the network or violates the rules and |

|||

protocols for communication across the network. |

|||

|

|||

Corresponding Source conveyed, and Installation Information provided, |

|||

in accord with this section must be in a format that is publicly |

|||

documented (and with an implementation available to the public in |

|||

source code form), and must require no special password or key for |

|||

unpacking, reading or copying. |

|||

|

|||

7. Additional Terms. |

|||

|

|||

"Additional permissions" are terms that supplement the terms of this |

|||

License by making exceptions from one or more of its conditions. |

|||

Additional permissions that are applicable to the entire Program shall |

|||

be treated as though they were included in this License, to the extent |

|||

that they are valid under applicable law. If additional permissions |

|||

apply only to part of the Program, that part may be used separately |

|||

under those permissions, but the entire Program remains governed by |

|||

this License without regard to the additional permissions. |

|||

|

|||

When you convey a copy of a covered work, you may at your option |

|||

remove any additional permissions from that copy, or from any part of |

|||

it. (Additional permissions may be written to require their own |

|||

removal in certain cases when you modify the work.) You may place |

|||

additional permissions on material, added by you to a covered work, |

|||

for which you have or can give appropriate copyright permission. |

|||

|

|||

Notwithstanding any other provision of this License, for material you |

|||

add to a covered work, you may (if authorized by the copyright holders of |

|||

that material) supplement the terms of this License with terms: |

|||

|

|||

a) Disclaiming warranty or limiting liability differently from the |

|||

terms of sections 15 and 16 of this License; or |

|||

|

|||

b) Requiring preservation of specified reasonable legal notices or |

|||

author attributions in that material or in the Appropriate Legal |

|||

Notices displayed by works containing it; or |

|||

|

|||

c) Prohibiting misrepresentation of the origin of that material, or |

|||

requiring that modified versions of such material be marked in |

|||

reasonable ways as different from the original version; or |

|||

|

|||

d) Limiting the use for publicity purposes of names of licensors or |

|||

authors of the material; or |

|||

|

|||

e) Declining to grant rights under trademark law for use of some |

|||

trade names, trademarks, or service marks; or |

|||

|

|||

f) Requiring indemnification of licensors and authors of that |

|||

material by anyone who conveys the material (or modified versions of |

|||

it) with contractual assumptions of liability to the recipient, for |

|||

any liability that these contractual assumptions directly impose on |

|||

those licensors and authors. |

|||

|

|||

All other non-permissive additional terms are considered "further |

|||

restrictions" within the meaning of section 10. If the Program as you |

|||

received it, or any part of it, contains a notice stating that it is |

|||

governed by this License along with a term that is a further |

|||

restriction, you may remove that term. If a license document contains |

|||

a further restriction but permits relicensing or conveying under this |

|||

License, you may add to a covered work material governed by the terms |

|||

of that license document, provided that the further restriction does |

|||

not survive such relicensing or conveying. |

|||

|

|||

If you add terms to a covered work in accord with this section, you |

|||

must place, in the relevant source files, a statement of the |

|||

additional terms that apply to those files, or a notice indicating |

|||

where to find the applicable terms. |

|||

|

|||

Additional terms, permissive or non-permissive, may be stated in the |

|||

form of a separately written license, or stated as exceptions; |

|||

the above requirements apply either way. |

|||

|

|||

8. Termination. |

|||

|

|||

You may not propagate or modify a covered work except as expressly |

|||

provided under this License. Any attempt otherwise to propagate or |

|||

modify it is void, and will automatically terminate your rights under |

|||

this License (including any patent licenses granted under the third |

|||

paragraph of section 11). |

|||

|

|||

However, if you cease all violation of this License, then your |

|||

license from a particular copyright holder is reinstated (a) |

|||

provisionally, unless and until the copyright holder explicitly and |

|||

finally terminates your license, and (b) permanently, if the copyright |

|||

holder fails to notify you of the violation by some reasonable means |

|||

prior to 60 days after the cessation. |

|||

|

|||

Moreover, your license from a particular copyright holder is |

|||

reinstated permanently if the copyright holder notifies you of the |

|||

violation by some reasonable means, this is the first time you have |

|||

received notice of violation of this License (for any work) from that |

|||

copyright holder, and you cure the violation prior to 30 days after |

|||

your receipt of the notice. |

|||

|

|||

Termination of your rights under this section does not terminate the |

|||

licenses of parties who have received copies or rights from you under |

|||

this License. If your rights have been terminated and not permanently |

|||

reinstated, you do not qualify to receive new licenses for the same |

|||

material under section 10. |

|||

|

|||

9. Acceptance Not Required for Having Copies. |

|||

|

|||

You are not required to accept this License in order to receive or |

|||

run a copy of the Program. Ancillary propagation of a covered work |

|||

occurring solely as a consequence of using peer-to-peer transmission |

|||

to receive a copy likewise does not require acceptance. However, |

|||

nothing other than this License grants you permission to propagate or |

|||

modify any covered work. These actions infringe copyright if you do |

|||

not accept this License. Therefore, by modifying or propagating a |

|||

covered work, you indicate your acceptance of this License to do so. |

|||

|

|||

10. Automatic Licensing of Downstream Recipients. |

|||

|

|||

Each time you convey a covered work, the recipient automatically |

|||

receives a license from the original licensors, to run, modify and |

|||

propagate that work, subject to this License. You are not responsible |

|||

for enforcing compliance by third parties with this License. |

|||

|

|||

An "entity transaction" is a transaction transferring control of an |

|||

organization, or substantially all assets of one, or subdividing an |

|||

organization, or merging organizations. If propagation of a covered |

|||

work results from an entity transaction, each party to that |

|||

transaction who receives a copy of the work also receives whatever |

|||

licenses to the work the party's predecessor in interest had or could |

|||

give under the previous paragraph, plus a right to possession of the |

|||

Corresponding Source of the work from the predecessor in interest, if |

|||

the predecessor has it or can get it with reasonable efforts. |

|||

|

|||

You may not impose any further restrictions on the exercise of the |

|||

rights granted or affirmed under this License. For example, you may |

|||

not impose a license fee, royalty, or other charge for exercise of |

|||

rights granted under this License, and you may not initiate litigation |

|||

(including a cross-claim or counterclaim in a lawsuit) alleging that |

|||

any patent claim is infringed by making, using, selling, offering for |

|||

sale, or importing the Program or any portion of it. |

|||

|

|||

11. Patents. |

|||

|

|||

A "contributor" is a copyright holder who authorizes use under this |

|||

License of the Program or a work on which the Program is based. The |

|||

work thus licensed is called the contributor's "contributor version". |

|||

|

|||

A contributor's "essential patent claims" are all patent claims |

|||

owned or controlled by the contributor, whether already acquired or |

|||

hereafter acquired, that would be infringed by some manner, permitted |

|||

by this License, of making, using, or selling its contributor version, |

|||

but do not include claims that would be infringed only as a |

|||

consequence of further modification of the contributor version. For |

|||

purposes of this definition, "control" includes the right to grant |

|||

patent sublicenses in a manner consistent with the requirements of |

|||

this License. |

|||

|

|||

Each contributor grants you a non-exclusive, worldwide, royalty-free |

|||

patent license under the contributor's essential patent claims, to |

|||

make, use, sell, offer for sale, import and otherwise run, modify and |

|||

propagate the contents of its contributor version. |

|||

|

|||

In the following three paragraphs, a "patent license" is any express |

|||

agreement or commitment, however denominated, not to enforce a patent |

|||

(such as an express permission to practice a patent or covenant not to |

|||

sue for patent infringement). To "grant" such a patent license to a |

|||

party means to make such an agreement or commitment not to enforce a |

|||

patent against the party. |

|||

|

|||

If you convey a covered work, knowingly relying on a patent license, |

|||

and the Corresponding Source of the work is not available for anyone |

|||

to copy, free of charge and under the terms of this License, through a |

|||

publicly available network server or other readily accessible means, |

|||

then you must either (1) cause the Corresponding Source to be so |

|||

available, or (2) arrange to deprive yourself of the benefit of the |

|||

patent license for this particular work, or (3) arrange, in a manner |

|||

consistent with the requirements of this License, to extend the patent |

|||

license to downstream recipients. "Knowingly relying" means you have |

|||

actual knowledge that, but for the patent license, your conveying the |

|||

covered work in a country, or your recipient's use of the covered work |

|||

in a country, would infringe one or more identifiable patents in that |

|||

country that you have reason to believe are valid. |

|||

|

|||

If, pursuant to or in connection with a single transaction or |

|||

arrangement, you convey, or propagate by procuring conveyance of, a |

|||

covered work, and grant a patent license to some of the parties |

|||

receiving the covered work authorizing them to use, propagate, modify |

|||

or convey a specific copy of the covered work, then the patent license |

|||

you grant is automatically extended to all recipients of the covered |

|||

work and works based on it. |

|||

|

|||

A patent license is "discriminatory" if it does not include within |

|||

the scope of its coverage, prohibits the exercise of, or is |

|||

conditioned on the non-exercise of one or more of the rights that are |

|||

specifically granted under this License. You may not convey a covered |

|||

work if you are a party to an arrangement with a third party that is |

|||

in the business of distributing software, under which you make payment |

|||

to the third party based on the extent of your activity of conveying |

|||

the work, and under which the third party grants, to any of the |

|||

parties who would receive the covered work from you, a discriminatory |

|||

patent license (a) in connection with copies of the covered work |

|||

conveyed by you (or copies made from those copies), or (b) primarily |

|||

for and in connection with specific products or compilations that |

|||

contain the covered work, unless you entered into that arrangement, |

|||

or that patent license was granted, prior to 28 March 2007. |

|||

|

|||

Nothing in this License shall be construed as excluding or limiting |

|||

any implied license or other defenses to infringement that may |

|||

otherwise be available to you under applicable patent law. |

|||

|

|||

12. No Surrender of Others' Freedom. |

|||

|

|||

If conditions are imposed on you (whether by court order, agreement or |

|||

otherwise) that contradict the conditions of this License, they do not |

|||

excuse you from the conditions of this License. If you cannot convey a |

|||

covered work so as to satisfy simultaneously your obligations under this |

|||

License and any other pertinent obligations, then as a consequence you may |

|||

not convey it at all. For example, if you agree to terms that obligate you |

|||

to collect a royalty for further conveying from those to whom you convey |

|||

the Program, the only way you could satisfy both those terms and this |

|||

License would be to refrain entirely from conveying the Program. |

|||

|

|||

13. Use with the GNU Affero General Public License. |

|||

|

|||

Notwithstanding any other provision of this License, you have |

|||

permission to link or combine any covered work with a work licensed |

|||

under version 3 of the GNU Affero General Public License into a single |

|||

combined work, and to convey the resulting work. The terms of this |

|||

License will continue to apply to the part which is the covered work, |

|||

but the special requirements of the GNU Affero General Public License, |

|||

section 13, concerning interaction through a network will apply to the |

|||

combination as such. |

|||

|

|||

14. Revised Versions of this License. |

|||

|

|||

The Free Software Foundation may publish revised and/or new versions of |

|||

the GNU General Public License from time to time. Such new versions will |

|||

be similar in spirit to the present version, but may differ in detail to |

|||

address new problems or concerns. |

|||

|

|||

Each version is given a distinguishing version number. If the |

|||

Program specifies that a certain numbered version of the GNU General |

|||

Public License "or any later version" applies to it, you have the |

|||

option of following the terms and conditions either of that numbered |

|||

version or of any later version published by the Free Software |

|||

Foundation. If the Program does not specify a version number of the |

|||

GNU General Public License, you may choose any version ever published |

|||

by the Free Software Foundation. |

|||

|

|||

If the Program specifies that a proxy can decide which future |

|||

versions of the GNU General Public License can be used, that proxy's |

|||

public statement of acceptance of a version permanently authorizes you |

|||

to choose that version for the Program. |

|||

|

|||

Later license versions may give you additional or different |

|||

permissions. However, no additional obligations are imposed on any |

|||

author or copyright holder as a result of your choosing to follow a |

|||

later version. |

|||

|

|||

15. Disclaimer of Warranty. |

|||

|

|||

THERE IS NO WARRANTY FOR THE PROGRAM, TO THE EXTENT PERMITTED BY |

|||

APPLICABLE LAW. EXCEPT WHEN OTHERWISE STATED IN WRITING THE COPYRIGHT |

|||

HOLDERS AND/OR OTHER PARTIES PROVIDE THE PROGRAM "AS IS" WITHOUT WARRANTY |

|||

OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, |

|||

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR |

|||

PURPOSE. THE ENTIRE RISK AS TO THE QUALITY AND PERFORMANCE OF THE PROGRAM |

|||

IS WITH YOU. SHOULD THE PROGRAM PROVE DEFECTIVE, YOU ASSUME THE COST OF |

|||

ALL NECESSARY SERVICING, REPAIR OR CORRECTION. |

|||

|

|||

16. Limitation of Liability. |

|||

|

|||

IN NO EVENT UNLESS REQUIRED BY APPLICABLE LAW OR AGREED TO IN WRITING |

|||

WILL ANY COPYRIGHT HOLDER, OR ANY OTHER PARTY WHO MODIFIES AND/OR CONVEYS |

|||

THE PROGRAM AS PERMITTED ABOVE, BE LIABLE TO YOU FOR DAMAGES, INCLUDING ANY |

|||

GENERAL, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE |

|||

USE OR INABILITY TO USE THE PROGRAM (INCLUDING BUT NOT LIMITED TO LOSS OF |

|||

DATA OR DATA BEING RENDERED INACCURATE OR LOSSES SUSTAINED BY YOU OR THIRD |

|||

PARTIES OR A FAILURE OF THE PROGRAM TO OPERATE WITH ANY OTHER PROGRAMS), |

|||

EVEN IF SUCH HOLDER OR OTHER PARTY HAS BEEN ADVISED OF THE POSSIBILITY OF |

|||

SUCH DAMAGES. |

|||

|

|||

17. Interpretation of Sections 15 and 16. |

|||

|

|||

If the disclaimer of warranty and limitation of liability provided |

|||

above cannot be given local legal effect according to their terms, |

|||

reviewing courts shall apply local law that most closely approximates |

|||

an absolute waiver of all civil liability in connection with the |

|||

Program, unless a warranty or assumption of liability accompanies a |

|||

copy of the Program in return for a fee. |

|||

|

|||

END OF TERMS AND CONDITIONS |

|||

|

|||

How to Apply These Terms to Your New Programs |

|||

|

|||

If you develop a new program, and you want it to be of the greatest |

|||

possible use to the public, the best way to achieve this is to make it |

|||

free software which everyone can redistribute and change under these terms. |

|||

|

|||

To do so, attach the following notices to the program. It is safest |

|||

to attach them to the start of each source file to most effectively |

|||

state the exclusion of warranty; and each file should have at least |

|||

the "copyright" line and a pointer to where the full notice is found. |

|||

|

|||

<one line to give the program's name and a brief idea of what it does.> |

|||

Copyright (C) <year> <name of author> |

|||

|

|||

This program is free software: you can redistribute it and/or modify |

|||

it under the terms of the GNU General Public License as published by |

|||

the Free Software Foundation, either version 3 of the License, or |

|||

(at your option) any later version. |

|||

|

|||

This program is distributed in the hope that it will be useful, |

|||

but WITHOUT ANY WARRANTY; without even the implied warranty of |

|||

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the |

|||

GNU General Public License for more details. |

|||

|

|||

You should have received a copy of the GNU General Public License |

|||

along with this program. If not, see <http://www.gnu.org/licenses/>. |

|||

|

|||

Also add information on how to contact you by electronic and paper mail. |

|||

|

|||

If the program does terminal interaction, make it output a short |

|||

notice like this when it starts in an interactive mode: |

|||

|

|||

<program> Copyright (C) <year> <name of author> |

|||

This program comes with ABSOLUTELY NO WARRANTY; for details type `show w'. |

|||

This is free software, and you are welcome to redistribute it |

|||

under certain conditions; type `show c' for details. |

|||

|

|||

The hypothetical commands `show w' and `show c' should show the appropriate |

|||

parts of the General Public License. Of course, your program's commands |

|||

might be different; for a GUI interface, you would use an "about box". |

|||

|

|||

You should also get your employer (if you work as a programmer) or school, |

|||

if any, to sign a "copyright disclaimer" for the program, if necessary. |

|||

For more information on this, and how to apply and follow the GNU GPL, see |

|||

<http://www.gnu.org/licenses/>. |

|||

|

|||

The GNU General Public License does not permit incorporating your program |

|||

into proprietary programs. If your program is a subroutine library, you |

|||

may consider it more useful to permit linking proprietary applications with |

|||

the library. If this is what you want to do, use the GNU Lesser General |

|||

Public License instead of this License. But first, please read |

|||

<http://www.gnu.org/philosophy/why-not-lgpl.html>. |

|||

@ -0,0 +1,83 @@ |

|||

# INAV - navigation capable flight controller |

|||

|

|||

|

|||

|

|||

## Features |

|||

|

|||

* Runs on the most popular F4 and F7 flight controllers |

|||

* Outstanding performance out of the box |

|||

* Position Hold, Altitude Hold, Return To Home and Missions |

|||

* Excellent support for fixed wing UAVs: airplanes, flying wings |

|||

* Fully configurable mixer that allows to run any hardware you want: multirotor, fixed wing, rovers, boats and other experimental devices |

|||

* Multiple sensor support: GPS, Pitot tube, sonar, lidar, temperature, ESC with BlHeli_32 telemetry |

|||

* SmartAudio and IRC Tramp VTX support |

|||

* Blackbox flight recorder logging |

|||

* On Screen Display (OSD) - both character and pixel style |

|||

* DJI OSD integration: all elements, system messages and warnings |

|||

* Telemetry: SmartPort, FPort, MAVlink, LTM |

|||

* Multi-color RGB LED Strip support |

|||

* Advanced gyro filtering: Matrix Filter and RPM filter |

|||

* Logic Conditions, Global Functions and Global Variables: you can program INAV with a GUI |

|||

* And many more! |

|||

|

|||

For a list of features, changes and some discussion please review consult the releases [page](https://github.com/iNavFlight/inav/releases) and the documentation. |

|||

|

|||

## Tools |

|||

|

|||

### INAV Configurator |

|||

|

|||

Official tool for INAV can be downloaded [here](https://github.com/iNavFlight/inav-configurator/releases). It can be run on Windows, MacOS and Linux machines and standalone application. |

|||

|

|||

### INAV Blackbox Explorer |

|||

|

|||

Tool for Blackbox logs analysis is available [here](https://github.com/iNavFlight/blackbox-log-viewer/releases) |

|||

|

|||

### Telemetry screen for OpenTX |

|||

|

|||

Users of OpenTX radios (Taranis, Horus, Jumper, Radiomaster, Nirvana) can use INAV OpenTX Telemetry Widget screen. Software and installation instruction are available here: [https://github.com/iNavFlight/OpenTX-Telemetry-Widget](https://github.com/iNavFlight/OpenTX-Telemetry-Widget) |

|||

|

|||

## Installation |

|||

|

|||

See: https://github.com/iNavFlight/inav/blob/master/docs/Installation.md |

|||

|

|||

## Documentation, support and learning resources |

|||

* [Fixed Wing Guide](docs/INAV_Fixed_Wing_Setup_Guide.pdf) |

|||

* [Autolaunch Guide](docs/INAV_Autolaunch.pdf) |

|||

* [Modes Guide](docs/INAV_Modes.pdf) |

|||

* [Wing Tuning Masterclass](docs/INAV_Wing_Tuning_Masterclass.pdf) |

|||

* [Official documentation](https://github.com/iNavFlight/inav/tree/master/docs) |

|||

* [Official Wiki](https://github.com/iNavFlight/inav/wiki) |

|||

* [INAV Official on Telegram](https://t.me/INAVFlight) |

|||

* [INAV Official on Facebook](https://www.facebook.com/groups/INAVOfficial) |

|||

* [RC Groups Support](https://www.rcgroups.com/forums/showthread.php?2495732-Cleanflight-iNav-(navigation-rewrite)-project) |

|||

* [Video series by Painless360](https://www.youtube.com/playlist?list=PLYsWjANuAm4qdXEGFSeUhOZ10-H8YTSnH) |

|||

* [Video series by Paweł Spychalski](https://www.youtube.com/playlist?list=PLOUQ8o2_nCLloACrA6f1_daCjhqY2x0fB) |

|||

|

|||

## Contributing |

|||

|

|||

Contributions are welcome and encouraged. You can contribute in many ways: |

|||

|

|||

* Documentation updates and corrections. |

|||

* How-To guides - received help? help others! |

|||

* Bug fixes. |

|||

* New features. |

|||

* Telling us your ideas and suggestions. |

|||

* Buying your hardware from this [link](https://inavflight.com/shop/u/bg/) |

|||

|

|||

A good place to start is Telegram channel or Facebook group. Drop in, say hi. |

|||

|

|||

Github issue tracker is a good place to search for existing issues or report a new bug/feature request: |

|||

|

|||

https://github.com/iNavFlight/inav/issues |

|||

|

|||

https://github.com/iNavFlight/inav-configurator/issues |

|||

|

|||

Before creating new issues please check to see if there is an existing one, search first otherwise you waste peoples time when they could be coding instead! |

|||

|

|||

## Developers |

|||

|

|||

Please refer to the development section in the [docs/development](https://github.com/iNavFlight/inav/tree/master/docs/development) folder. |

|||

|

|||

|

|||

## INAV Releases |

|||

https://github.com/iNavFlight/inav/releases |

|||

@ -0,0 +1,32 @@ |

|||

# -*- mode: ruby -*- |

|||

# vi: set ft=ruby : |

|||

|

|||

# All Vagrant configuration is done below. The "2" in Vagrant.configure |

|||

# configures the configuration version (we support older styles for |

|||

# backwards compatibility). Please don't change it unless you know what |

|||

# you're doing. |

|||

Vagrant.configure(2) do |config| |

|||

# The most common configuration options are documented and commented below. |

|||

# For a complete reference, please see the online documentation at |

|||

# https://docs.vagrantup.com. |

|||

|

|||

# Every Vagrant development environment requires a box. You can search for |

|||

# boxes at https://atlas.hashicorp.com/search. |

|||

config.vm.box = "ubuntu/trusty64" |

|||

config.vm.synced_folder ".", "/home/vagrant/inav" |

|||

config.vm.hostname = "iNavDev" |

|||

config.vm.define "iNavDev" |

|||

config.vm.provider :virtualbox do |vb| |

|||

vb.name = "iNavDev" |

|||

end |

|||

# Enable provisioning with a shell script. Additional provisioners such as |

|||

# Puppet, Chef, Ansible, Salt, and Docker are also available. Please see the |

|||

# documentation for more information about their specific syntax and use. |

|||

config.vm.provision "shell", inline: <<-SHELL |

|||

sudo apt-get remove -y --force-yes gcc-arm-none-eabi ruby |

|||

sudo apt-add-repository ppa:brightbox/ruby-ng |

|||

sudo add-apt-repository ppa:team-gcc-arm-embedded/ppa |

|||

sudo apt-get update |

|||

sudo apt-get install -y --force-yes git gcc-arm-embedded ruby2.4 ruby2.4-dev |

|||

SHELL |

|||

end |

|||

@ -0,0 +1,32 @@ |

|||

set -e |

|||

|

|||

if [[ $# == 0 ]]; then |

|||

echo -e "\ |

|||

Usage syntax: ./build.sh <TARGET> |

|||

|

|||

Notes: |

|||

* You can specify multiple targets. |

|||

* If no targets are specified, *all* of them will be built. |

|||

* To clean a target prefix it with \"clean_\". |

|||

* To clean all targets just use \"clean\"." |

|||

exit 1 |

|||

fi |

|||

|

|||

if [ -z "$(docker images -q inav-build)" ]; then |

|||

echo -e "*** Building image\n" |

|||

docker build -t inav-build . |

|||

echo -ne "\n" |

|||

fi |

|||

|

|||

if [ ! -d ./build ]; then |

|||

echo -e "*** Creating build directory\n" |

|||

mkdir ./build |

|||

fi |

|||

|

|||

echo -e "*** Building targets [$@]\n" |

|||

docker run --rm -it -v "$(pwd)":/src inav-build $@ |

|||

|

|||

if ls ./build/*.hex &> /dev/null; then |

|||

echo -e "\n*** Built targets in ./build:" |

|||

stat -c "%n (%.19y)" ./build/*.hex |

|||

fi |

|||

@ -0,0 +1,60 @@ |

|||

#!/bin/bash |

|||

|

|||

filename=Manual |

|||

doc_files=( |

|||

'Introduction.md' |

|||

'Getting Started.md' |

|||

'Safety.md' |

|||

'Installation.md' |

|||

'Configuration.md' |

|||

'Cli.md' |

|||

'Serial.md' |

|||

'Rx.md' |

|||

'Spektrum bind.md' |

|||

'Failsafe.md' |

|||

'Battery.md' |

|||

'Gps.md' |

|||

'Rssi.md' |

|||

'Telemetry.md' |

|||

'LedStrip.md' |

|||

'Display.md' |

|||

'Buzzer.md' |

|||

'Sonar.md' |

|||

'Profiles.md' |

|||

'Modes.md' |

|||

'Inflight Adjustments.md' |

|||

'Controls.md' |

|||

'Gtune.md' |

|||

'Blackbox.md' |

|||

'Migrating from baseflight.md' |

|||

'Boards.md' |

|||

'Board - AlienFlight.md' |

|||

'Board - ColibriRace.md' |

|||

'Board - Motolab.md' |

|||

'Board - Paris Air Hero 32.md' |

|||

'Board - Sparky.md' |

|||

'Board - RMDO.md' |

|||

'Board - SPRacingF3.md' |

|||

) |

|||

|

|||

if which gimli >/dev/null; then |

|||

echo "Building ${filename}.pdf" |

|||

pushd . >/dev/null |

|||

cd docs |

|||

|

|||

rm -f ${filename}.md |

|||

for i in "${doc_files[@]}" |

|||

do |

|||

cat "$i" >> ${filename}.md |

|||

done |

|||

rm -f ${filename}.pdf |

|||

gimli -f ${filename}.md -stylesheet override.css \ |

|||

-w '--toc --title "Cleanflight Manual" --footer-right "[page]" --toc-depth 1' |

|||

rm ${filename}.md |

|||

popd >/dev/null |

|||

else |

|||

echo -e "\nFAILED" |

|||

echo "Install Gimli to build the PDF documentation" |

|||

echo -e "https://github.com/walle/gimli\n" |

|||

exit 1 |

|||

fi |

|||

@ -0,0 +1,172 @@ |

|||

# - Returns a version string from Git |

|||

# |

|||

# These functions force a re-configure on each git commit so that you can |

|||

# trust the values of the variables in your build system. |

|||

# |

|||

# get_git_head_revision(<refspecvar> <hashvar> [<additional arguments to git describe> ...]) |

|||

# |

|||

# Returns the refspec and sha hash of the current head revision |

|||

# |

|||

# git_describe(<var> [<additional arguments to git describe> ...]) |

|||

# |

|||

# Returns the results of git describe on the source tree, and adjusting |

|||

# the output so that it tests false if an error occurs. |

|||

# |

|||

# git_get_exact_tag(<var> [<additional arguments to git describe> ...]) |

|||

# |

|||

# Returns the results of git describe --exact-match on the source tree, |

|||

# and adjusting the output so that it tests false if there was no exact |

|||

# matching tag. |

|||

# |

|||

# git_local_changes(<var>) |

|||

# |

|||

# Returns either "CLEAN" or "DIRTY" with respect to uncommitted changes. |

|||

# Uses the return code of "git diff-index --quiet HEAD --". |

|||

# Does not regard untracked files. |

|||

# |

|||

# Requires CMake 2.6 or newer (uses the 'function' command) |

|||

# |

|||

# Original Author: |

|||

# 2009-2010 Ryan Pavlik <rpavlik@iastate.edu> <abiryan@ryand.net> |

|||

# http://academic.cleardefinition.com |

|||

# Iowa State University HCI Graduate Program/VRAC |

|||

# |

|||

# Copyright Iowa State University 2009-2010. |

|||

# Distributed under the Boost Software License, Version 1.0. |

|||

# (See accompanying file LICENSE_1_0.txt or copy at |

|||

# http://www.boost.org/LICENSE_1_0.txt) |

|||

|

|||

if(__get_git_revision_description) |

|||

return() |

|||

endif() |

|||

set(__get_git_revision_description YES) |

|||

|

|||

# We must run the following at "include" time, not at function call time, |

|||

# to find the path to this module rather than the path to a calling list file |

|||

get_filename_component(_gitdescmoddir ${CMAKE_CURRENT_LIST_FILE} PATH) |

|||

|

|||

function(get_git_head_revision _refspecvar _hashvar) |

|||

set(GIT_PARENT_DIR "${CMAKE_CURRENT_SOURCE_DIR}") |

|||

set(GIT_DIR "${GIT_PARENT_DIR}/.git") |

|||

while(NOT EXISTS "${GIT_DIR}") # .git dir not found, search parent directories |

|||

set(GIT_PREVIOUS_PARENT "${GIT_PARENT_DIR}") |

|||

get_filename_component(GIT_PARENT_DIR ${GIT_PARENT_DIR} PATH) |

|||

if(GIT_PARENT_DIR STREQUAL GIT_PREVIOUS_PARENT) |

|||

# We have reached the root directory, we are not in git |

|||

set(${_refspecvar} "GITDIR-NOTFOUND" PARENT_SCOPE) |

|||

set(${_hashvar} "GITDIR-NOTFOUND" PARENT_SCOPE) |

|||

return() |

|||

endif() |

|||

set(GIT_DIR "${GIT_PARENT_DIR}/.git") |

|||

endwhile() |

|||

# check if this is a submodule |

|||

if(NOT IS_DIRECTORY ${GIT_DIR}) |

|||

file(READ ${GIT_DIR} submodule) |

|||

string(REGEX REPLACE "gitdir: (.*)\n$" "\\1" GIT_DIR_RELATIVE ${submodule}) |

|||

get_filename_component(SUBMODULE_DIR ${GIT_DIR} PATH) |

|||

get_filename_component(GIT_DIR ${SUBMODULE_DIR}/${GIT_DIR_RELATIVE} ABSOLUTE) |

|||

endif() |

|||

if(NOT IS_DIRECTORY "${GIT_DIR}") |

|||

file(READ ${GIT_DIR} worktree) |

|||

string(REGEX REPLACE "gitdir: (.*)worktrees(.*)\n$" "\\1" GIT_DIR ${worktree}) |

|||

endif() |

|||

set(GIT_DATA "${CMAKE_CURRENT_BINARY_DIR}/CMakeFiles/git-data") |

|||

if(NOT EXISTS "${GIT_DATA}") |

|||

file(MAKE_DIRECTORY "${GIT_DATA}") |

|||

endif() |

|||

|

|||

if(NOT EXISTS "${GIT_DIR}/HEAD") |

|||

return() |

|||

endif() |

|||

set(HEAD_FILE "${GIT_DATA}/HEAD") |

|||

configure_file("${GIT_DIR}/HEAD" "${HEAD_FILE}" COPYONLY) |

|||

|

|||

configure_file("${_gitdescmoddir}/GetGitRevisionDescription.cmake.in" |

|||

"${GIT_DATA}/grabRef.cmake" |

|||

@ONLY) |

|||

include("${GIT_DATA}/grabRef.cmake") |

|||

|

|||

set(${_refspecvar} "${HEAD_REF}" PARENT_SCOPE) |

|||

set(${_hashvar} "${HEAD_HASH}" PARENT_SCOPE) |

|||

endfunction() |

|||

|

|||

function(git_describe _var) |

|||

if(NOT GIT_FOUND) |

|||

find_package(Git QUIET) |

|||

endif() |

|||

get_git_head_revision(refspec hash) |

|||

if(NOT GIT_FOUND) |

|||

set(${_var} "GIT-NOTFOUND" PARENT_SCOPE) |

|||

return() |

|||

endif() |

|||

if(NOT hash) |

|||

set(${_var} "HEAD-HASH-NOTFOUND" PARENT_SCOPE) |

|||

return() |

|||

endif() |

|||

|

|||

# TODO sanitize |

|||

#if((${ARGN}" MATCHES "&&") OR |

|||

# (ARGN MATCHES "||") OR |

|||

# (ARGN MATCHES "\\;")) |

|||

# message("Please report the following error to the project!") |

|||

# message(FATAL_ERROR "Looks like someone's doing something nefarious with git_describe! Passed arguments ${ARGN}") |

|||

#endif() |

|||

|

|||

#message(STATUS "Arguments to execute_process: ${ARGN}") |

|||

|

|||

execute_process(COMMAND |

|||

"${GIT_EXECUTABLE}" |

|||

describe |

|||

${hash} |

|||

${ARGN} |

|||

WORKING_DIRECTORY |

|||

"${CMAKE_CURRENT_SOURCE_DIR}" |

|||

RESULT_VARIABLE |

|||

res |

|||

OUTPUT_VARIABLE |

|||

out |

|||

ERROR_QUIET |

|||

OUTPUT_STRIP_TRAILING_WHITESPACE) |

|||

if(NOT res EQUAL 0) |

|||

set(out "${out}-${res}-NOTFOUND") |

|||

endif() |

|||

|

|||

set(${_var} "${out}" PARENT_SCOPE) |

|||

endfunction() |

|||

|

|||

function(git_get_exact_tag _var) |

|||

git_describe(out --exact-match ${ARGN}) |

|||

set(${_var} "${out}" PARENT_SCOPE) |

|||

endfunction() |

|||

|

|||

function(git_local_changes _var) |

|||

if(NOT GIT_FOUND) |

|||

find_package(Git QUIET) |

|||

endif() |

|||

get_git_head_revision(refspec hash) |

|||

if(NOT GIT_FOUND) |

|||

set(${_var} "GIT-NOTFOUND" PARENT_SCOPE) |

|||

return() |

|||

endif() |

|||

if(NOT hash) |

|||

set(${_var} "HEAD-HASH-NOTFOUND" PARENT_SCOPE) |

|||

return() |

|||

endif() |

|||

|

|||

execute_process(COMMAND |

|||

"${GIT_EXECUTABLE}" |

|||

diff-index --quiet HEAD -- |

|||

WORKING_DIRECTORY |

|||

"${CMAKE_CURRENT_SOURCE_DIR}" |

|||

RESULT_VARIABLE |

|||

res |

|||

OUTPUT_VARIABLE |

|||

out |

|||

ERROR_QUIET |

|||

OUTPUT_STRIP_TRAILING_WHITESPACE) |

|||

if(res EQUAL 0) |

|||

set(${_var} "CLEAN" PARENT_SCOPE) |

|||

else() |

|||

set(${_var} "DIRTY" PARENT_SCOPE) |

|||

endif() |

|||

endfunction() |

|||

@ -0,0 +1,41 @@ |

|||

# |

|||

# Internal file for GetGitRevisionDescription.cmake |

|||

# |

|||

# Requires CMake 2.6 or newer (uses the 'function' command) |

|||

# |

|||

# Original Author: |

|||

# 2009-2010 Ryan Pavlik <rpavlik@iastate.edu> <abiryan@ryand.net> |

|||